The continued growth of hybrid (HEV) and electric vehicles (EV) brings new challenges, such as the accumulation of spent NiMH and Li-ion batteries. It’s estimated that the number of electric vehicles on the road is expected to reach 300 million by 2030, from 10 million currently in 2022, and 1.7 million EV batteries will be decommissioned from vehicles and ready for either second-life applications or recycling.

A3 Global focuses on extending the useful vehicle life of these batteries through reconditioning and remanufacturing. However, some used battery cells and modules are still too weak for the original, high-power demand. Instead of disposing of or recycling the batteries, they can be repurposed for energy storage in lower-stress applications.

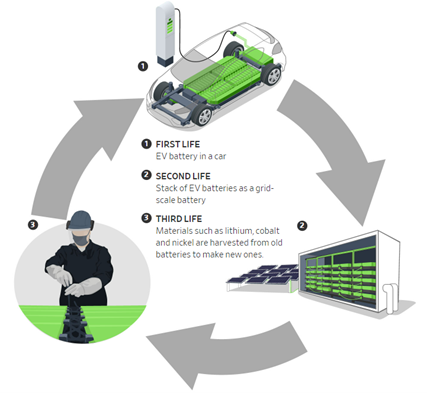

Automakers are implementing a few novel ideas to keep these batteries in use. Projects include Nissan EV batteries powering a soccer stadium in Amsterdam, a 30-megawatt energy storage system at Rome Fiumicino Airport, and Volkswagen using EV batteries to store energy at charging stations. The diagram below shows the proposed three-stage life cycle for EV batteries.

Challenging life cycle issues include: 1) lower costs of new batteries, 2) varying types of battery chemistry, format, and design, and 3) establishing specifications for grid-use batteries. Companies must weigh the costs of repurposing spent batteries versus simply manufacturing new ones and 4) the diversity of battery chemistries and formats making it difficult to design uniform large-scale solutions. The above issues demand the development of new, broadly applicable analytical tools and protocols.

Repurposed vehicle batteries are now being evaluated for solar power backup in microgrids. The Technology and Education Center for Renewable Energy has deployed Toyota hybrid vehicle battery modules in a recent solar microgrid demonstration. TECRE, a Puerto Rican 501(c)(3), was founded by Dr. Eugene Smotkin to promote alternative energy solutions through experiential education. Hurricane Maria, and more recently Fiona has devastated the Puerto Rican electric infrastructure. Five years after Maria, there are still blue tarps in rural towns like Utuado. Repurposing Toyota modules for energy storage changes a linear cradle-to-grave lifecycle into a more sustainable circular lifecycle. The reduction of system costs is especially important in a locality where 54 percent of residents live below the poverty level. The solar energy storage system was designed collaboratively between TECRE and Northeastern University, using reconditioned modules provided by NuVant Systems, an A3 Global Company.

An initial model installation (above) was completed on the Northeastern University campus a few months before, using a repurposed 28-module Toyota Prius pack. The trial system powered some household appliances, including light bulbs and fans.

The success of the design model translated to real-life efforts in Utuado. The 1.2 kW solar panel was installed onto the home’s metal roof (Fig 3). Extra restraints were added due to potential damage from high winds during hurricane season. A 1.8 kWh battery was custom-built from 40 repurposed Toyota modules to store the energy generated by the solar panels. The system was then wired directly into the home, allowing the family to switch between the battery and the electrical grid. The project demonstrates that even a small, affordable solar energy system can significantly impact residents’ daily lives.

A3 Global is now extending their proprietary process for reconditioning and/or battery module balancing to lithium ion batteries. From reconditioning, remanufacturing and finally repurposing, the longer we can extend battery shelf life, the better it is for the EV industry, the economy, and the environment. To subscribe to our monthly newsletter, click here. To contact us on your second-life battery project, click here.