Hybrid reconditioning is a process of bringing new life into battery packs when they have fallen below their optimal condition. Over time, the cells within hybrid vehicle batteries begin to wear out and fail leading to diminished performance, reduced fuel efficiency and eventually the battery will die. As batteries diminish, vehicle owners have a choice: you can replace your battery or recondition it. Reconditioning is cheaper and better for the environment, bringing your old battery back to life. In this guide, we will help you understand how reconditioning works and if it’s the right choice for you.

(Is your shop thinking about offering reconditioning services? Read this first )

Why recondition or repair hybrid batteries

All batteries eventually deteriorate. As their performance diminishes, drivers will notice that their electric hybrid batteries will be unable to hold a charge like they once did and the power of the motor will be reduced. When this happens a battery can be replaced or reconditioned. Both options will provide a drastic boost in performance and increased fuel efficiency. But, why recondition when you can buy a new battery?

Reconditioning/Repair vs buying new batteries

The process of reconditioning a battery and buying a new or replacement battery can both yield a battery with optimal performance and functionality. However there are pros and cons of each.

Benefits of reconditioning hybrid batteries:

Reconditioning batteries is a great way to restore usability in an affordable way. Buying a brand new hybrid battery can cost several thousand (US) dollars where as reconditioning one is a fraction of the cost. This is also a quick and easy way to extend the usability during times when new hybrid batteries are difficult to access due to marketplace availability or shipping delays.

Benefits of buying replacement hybrid batteries:

Replacing a hybrid battery, while more expensive then reconditioning, can provide longer operating functionality. There are also different replacement options. A hybrid vehicle owner can choose to replace their battery with a brand new battery or go the more cost effective route and purchase a remanufactured hybrid battery.

What’s the best option?

The best option really comes down to the vehicle owner’s wants and needs. Some, may like the idea of saving money and doing their part to protect the environment by reconditioning their old batteries. Others are OK with spending the premium to buy a new hybrid battery because they want the convenience and the warranty.

How to recondition hybrid batteries

Reconditioning a hybrid battery consists of charging, discharging and balancing the battery pack. This process breaks down the voltage depressions within a battery’s cells restoring the usable capacity and balancing the voltage levels between each cell. At the end of the reconditioning process the battery will have a better capacity output for the vehicle to utilize.

Reconditioning can be a relatively easy process for those who have the proper knowledge and the right equipment. Here is a simplified version of the steps it takes to recondition hybrid batteries:

- Inspect the battery

- Remove and replace any broken modules

- Charge and discharge modules in parallel

- Use a hybrid battery reconditioning tool for this step

- Test battery output

With the right tools, equipment and expertise, reconditioning can become a valuable resource for repairing hybrid vehicles. Here’s a video that demonstrates how to recondition and repair a hybrid electric vehicle battery with reconditioning equipment. https://youtu.be/IImnqNn6NXA

Examples of EVc output before and after conditioning

There are some who are skeptical of how well reconditioning works. To get a true understanding of what reconditioning does and how well it works, you have to see it in action. Below you will see real examples of EVc output files for popular traction battery packs.

Toyota Highlander Reconditioning Data

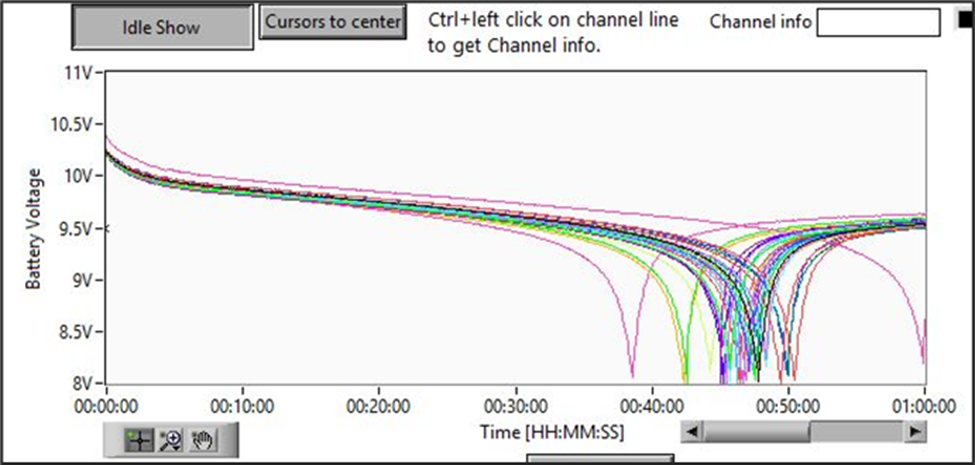

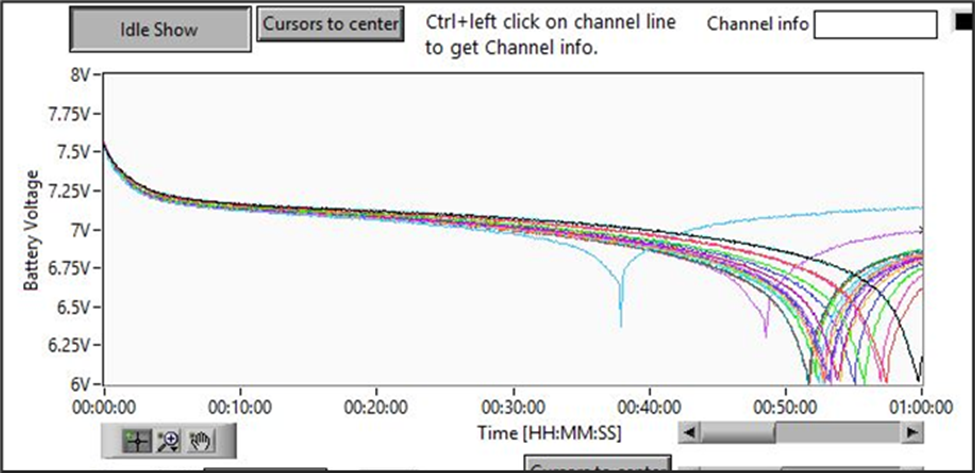

EVc data from Toyota Highlander Pack (before reconditioning)

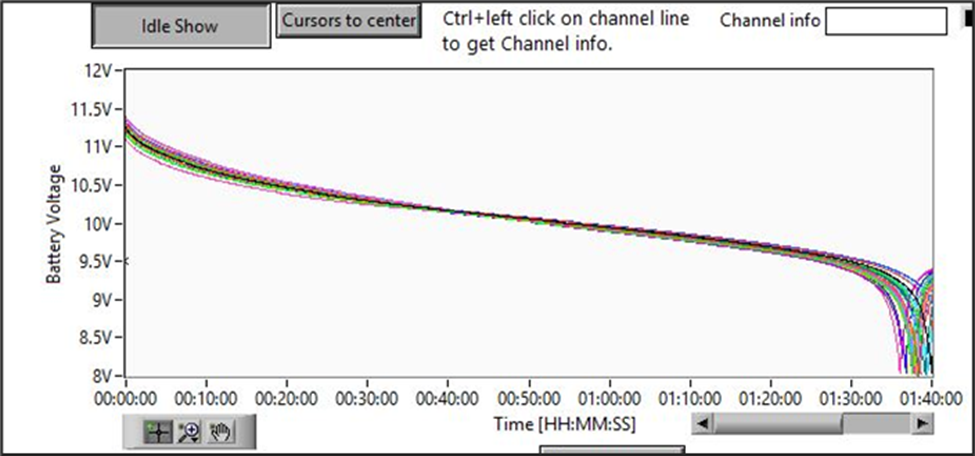

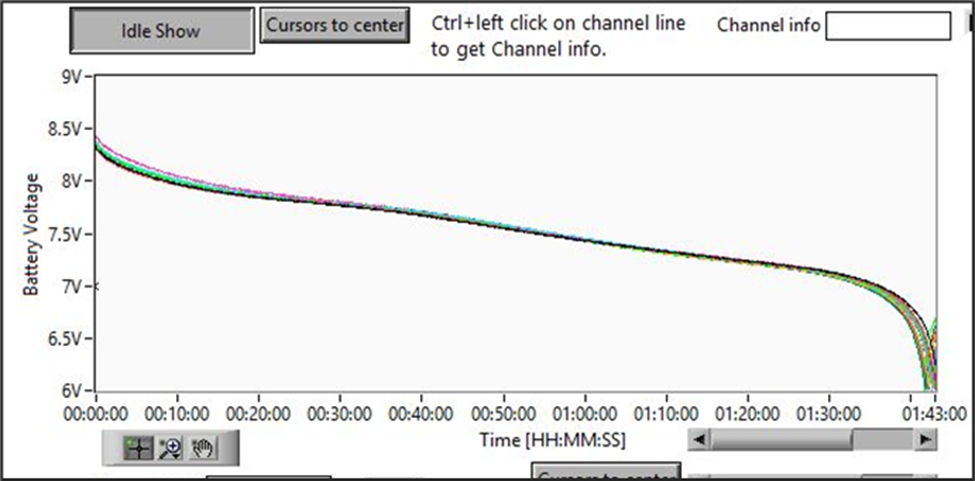

Toyota Highlander EVc data (after reconditioning)

Ford Escape Battery Reconditioning Data

Ford Escape EVc data (before reconditioning)

Ford Escape EVc data (after reconditioning)

Toyota Prius Reconditioning Data

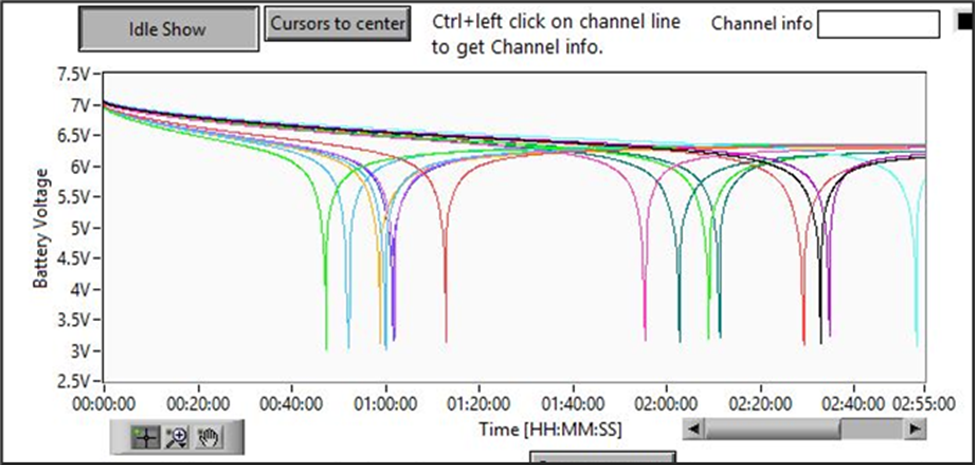

Toyota Prius EVc data (before reconditioning)

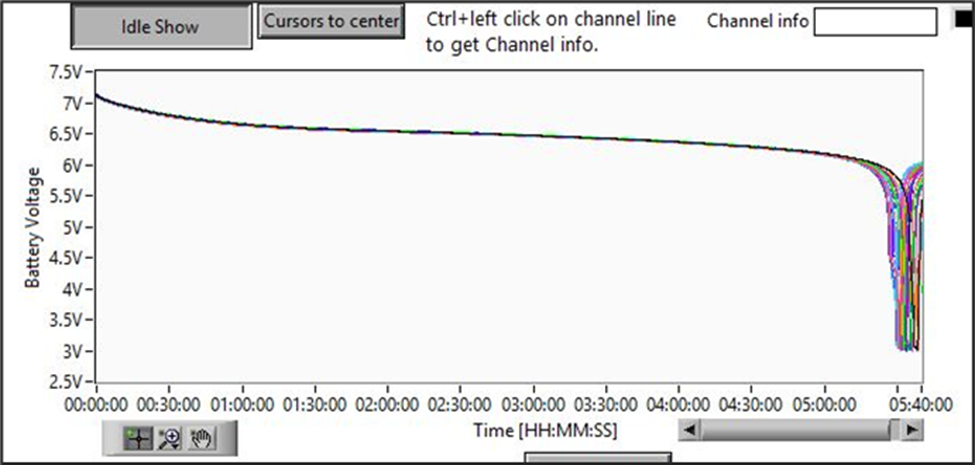

Toyota Prius EVc data (after reconditioning)

How long does it take to recondition a hybrid battery pack?

High quality cell balancing requires a minimum of 20 hours on the EVc tool. NiMH modules have system parameters specific to the form factor (e.g., prismatic versus cylindrical) and number of cells in series (e.g., Ford Escape: 5; Prius prismatic: 6; etc.). These parameters govern the choice of recipe parameters. Balancing recipes and their automated implementation are covered in the NuVant battery reconditioning course. The business model is: 1. Establish an inventory of reconditioned modules archived with watt-hour capacity and nominal module voltage data. 2. Replace customer hybrid batteries. 3. Recovery the battery core from the customer.

What tools are required for hybrid battery reconditioning and repair?

When it comes to reconditioning hybrid batteries, there is some equipment and tools that are required.

The required tools are (1) a menu driven charge discharge cycler (the EVc tool), (2) software for analysis of amp-hour capacity and midpoint voltage data on every module maintained in inventory, (3) a QR code reader and (4) a 50 inch-pound torque limited nut driver.

Our top selling Hybrid Battery Repair Tool is the EVc-30. When purchasing, it includes the EVc unit, training and EVc software (EVcharge). EVcharge imports module state-of-health data from the EVc-30.

Hybrid battery reconditioning Information for Shop owners and Businesses

As the vehicle market rapidly changes, many garages and auto shops wonder if adding a hybrid battery reconditioning service is worth the time, effort and investment.

Electric and hybrid vehicle sales in the United States nearly doubled from 2020 to 2021. As more and more consumers are turning to electric and hybrid vehicles, they will seek reconditioning as a cost-effective solution to repairing their batteries.

For a business owner to decide whether a service is right for them, they need to consider more than if there is a market for the product. As you’ve discovered earlier in this guide, there is equipment required and knowledge to implement this type of service. We find that owners ask themselves three main questions when thinking about adding a reconditioning service to their offerings:

- Is there a market for it

- Are our people capable of learning the necessary skills

- Is the investment worth it?

At NuVant, when we sell reconditioning equipment we offer training on how to use the tools. We also provide free educational webinars every month as refresher courses or to help mechanics hone their skills. We believe that the use of the HEV tools shouldn’t be the thing that stops businesses from reconditioning batteries.

This leaves the main question of is it worth it, up to the individual shop owners. Here is a blog article that breaks down the ROI of hybrid battery reconditioning to help you understand the numbers. However at the end of the day, it’s up to you to decide if it’s worth your investment.

While reconditioning equipment is out of reach for most consumers, it’s a great investment for shop and fleet owners. This creates a win-win situation for both shops and consumers. Consumers have a chance to save by reconditioning rather than fully replacing their batteries, fleet owners can benefit in a similar fashion, and shop owners have an opportunity to generate a positive return on their investment easily within the first year of implementing this service.

The first step for your shop is to purchase the required equipment. Click here to request a quote. If you would like to speak with someone about what’s required to make this work for your shop, then contact us and we can help you understand the process.