In recognition of Climate Week, which is celebrated between the days of Sept. 21-28, A3 Global has outlined the current state of the battery remanufacturing industry and the environmental and economical benefits of remanufacturing over battery shredding or outright disposal. Whether you’ve been involved in remanufacturing for a long time or you’re looking to get involved, this article has something for you.

Car battery remanufacturing is one of the most effective ways to cut greenhouse gas emissions, reduce reliance on mining, and strengthen the hybrid and electric vehicle battery supply chains. Remanufacturing lithium-ion and nickel-metal hydride batteries uses up to 89% less energy and produces up to 81% fewer emissions than sourcing new materials according to a study published by Stanford. It also creates a multibillion-dollar economic opportunity by recovering valuable minerals like lithium, nickel, and cobalt for reuse in new batteries. As more hybrid and electric vehicles reach end-of-life, A3 Global and NuVant are leading the way with advanced tools that make battery diagnostics, reconditioning, and second-life applications easier, faster, and more profitable.

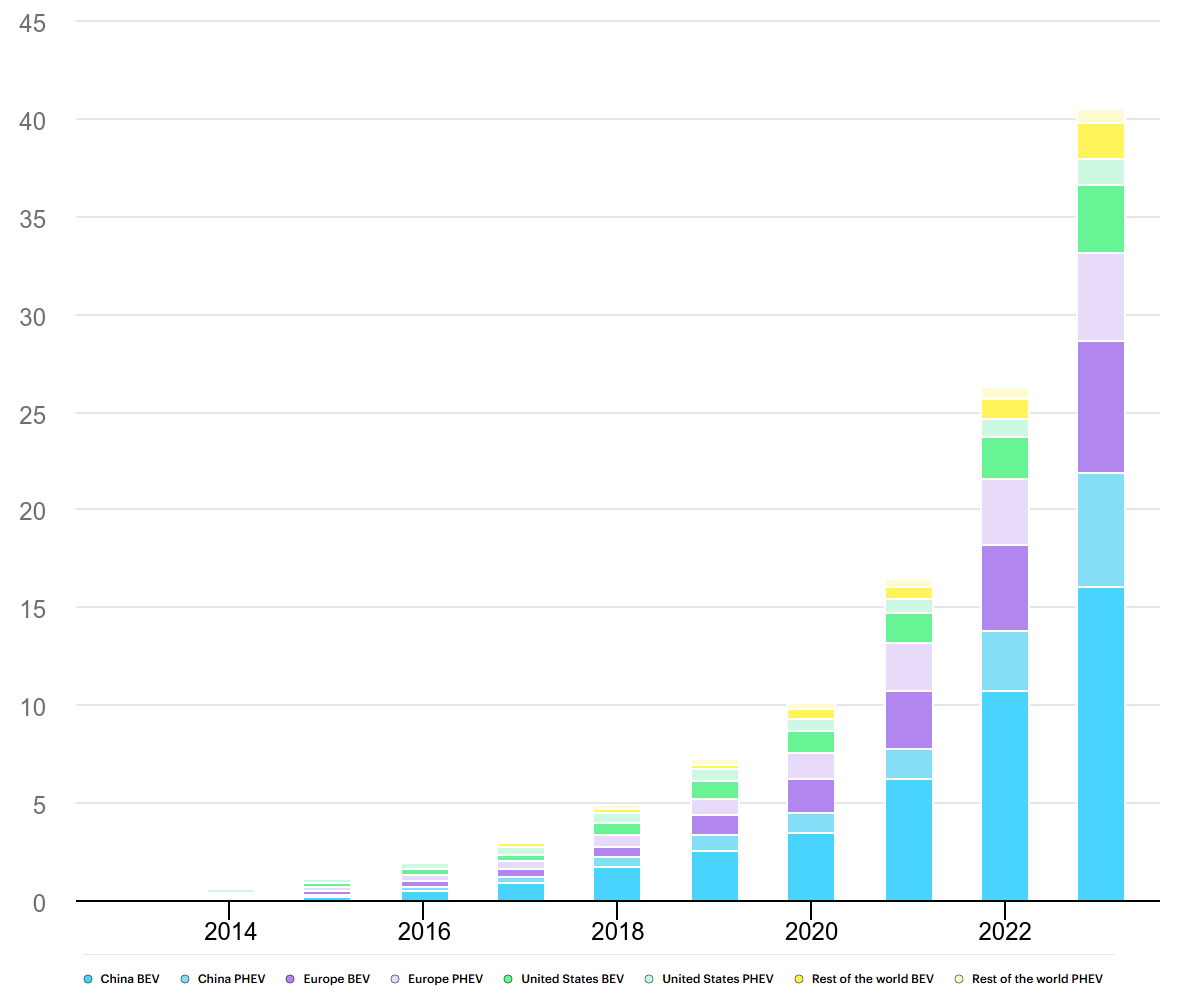

The growing need for battery remanufacturing

Every electric and hybrid vehicle on the road today depends on high-value minerals like lithium, nickel, cobalt, and rare earth elements. Mining and refining these materials comes with significant environmental costs, like high carbon emissions, water consumption, and long, fragile supply chains. Remanufacturing end-of-life car batteries provides a solution: it reduces the need for virgin mining, lowers emissions, strengthens domestic supply chains, and creates economic opportunities in a rapidly expanding secondary market.

By integrating remanufacturing into your business’s Climate Week commitments, your organization can make measurable strides toward sustainability while participating in one of the fastest-growing clean technology markets.

Leading the way, not keeping up

For businesses looking to thrive in the next decade, adapting to battery remanufacturing is more profitable than simply keeping up with the status quo of purchasing batteries made from newly mined materials. Not only are recycled batteries more valuable than scrapped ones, with the total societal value of battery remanufacturing in the U.S. projected to reach $11-$40 billion by 2040, but the environmental and social costs of remanufacturing are significantly lower than mining. Studies show that remanufacturing lithium-ion batteries can cut emissions by up to three-fourths and reduce energy and water usage dramatically compared to virgin mining. As global demand grows and accessible mineral reserves shrink, the cost of new mining will become increasingly unsustainable for both businesses and consumers. Those who pivot now toward remanufacturing will secure higher margins and protect themselves from the volatility of raw material markets.

Adapting to supply chain issues

Global supply chains for battery minerals are notoriously long and fragile, often stretching tens of thousands of miles and relying on mining practices that raise human rights and environmental concerns. These chains are vulnerable to disruption, price shocks, and geopolitical instability. Remanufacturing changes that equation by creating a shorter, more local loop for critical materials, reducing dependence on uncertain imports and inhumane working conditions.

According to the EPA, lithium-ion battery remanufacturing also prevents hazardous waste from being improperly disposed of, helping build a circular and sustainable economy. By choosing remanufacturing over mining, businesses can support a fairer, more stable world economy while ensuring the steady flow of materials needed for the batteries of the future.

Compatibility and scalability in the battery remanufacturing aftermarket

The landscape of battery technology is evolving rapidly. Nickel-metal hydride batteries remain prevalent in hybrids still on the road, but lithium-ion batteries, popularized by EVs like Tesla, are increasingly entering the aftermarket. Businesses that want to succeed in remanufacturing must be prepared to service both battery types. In collaboration with Northeastern University, A3 Global and NuVant are leading the way in research and development of battery remanufacturing technology that responds to the needs of the battery aftermarket. NuVant’s LVc-40 offers advanced diagnostics and reconditioning for both NiMH and Li-ion chemistries, the first of its kind to do so. With the ability to handle today’s hybrid batteries and tomorrow’s EV batteries, the LVc-40 positions businesses to scale and adapt as the market continues to shift, ensuring they remain competitive and future-ready.

NuVant powers battery recyclers

NuVant has been advancing electrochemical technology for decades, with a mission to “bring electrochemistry to the streets.” Our focus is making cutting-edge science accessible to shops, recyclers, and businesses that want to participate in the EV and hybrid aftermarket.

-

LVc-40 – Our flagship EV cell diagnostic tool and HEV reconditioner, offering unmatched ROI, Li-ion and NiMH compatibility, and throughput advantages

-

EVc-30 – A simplified, turnkey reconditioning unit designed for hybrid battery packs, ideal for smaller operators entering the remanufacturing market

-

EVd-40 Power Tester – A triage tool that helps recyclers unlock second-life opportunities and maximize profits by identifying reusable modules

At NuVant, we are proud to support businesses looking to align with Climate Week’s green goals. By combining education, sustainability, and cutting-edge tools, we help our partners not only meet their environmental goals but also thrive in the growing circular economy of battery remanufacturing.