The race is on to get higher efficiency, lower operating costs, and more sustainable fleet vehicles. While there has been a focus on new EVs, buying a brand-new EV fleet is simply unrealistic for most fleet organizations. Converting fleets from existing internal combustion engines (ICE) to EVs is a smart alternative to all new EVs.

This conversion process, also known as the electrification of vehicles, is a speedy and cost-effective way to replace an ICE fleet with electric vehicles. Let A3 Global be your conversion partner–our team brings decades of aftermarket experience to provide turnkey electrification solutions to fleets. In this article, we will explain what electrification is and the process so you can make informed decisions for your company’s fleet.

What is the electrification of vehicles?

The concept of electrification of ICE vehicles is simple. Internal combustion engines can be converted to all-electric by removing the engine and associated components and then replacing them with an EV battery pack, electric motor, power electronics, and other electrical components.

After being converted, the vehicle will not just run like an EV vehicle, but it will be an EV by definition. This means that a converted vehicle will run on a battery rather than gasoline and require charging.

With increasing government regulatory requirements and companies making more ESG-conscious decisions, there are many reasons why an organization would want to convert its fleet to electric.

Why Convert your ICE Fleet to an EV Fleet?

For most organizations, converting their fleet from ICE to EV just makes sense for a number of reasons:

- Already invested in large numbers of ICE vehicles, and it would be a challenge to replace an all-new EV fleet with EVs in the short term

- Many organizations spend significant funds–often tens of thousands of dollars–to custom-fit their interiors with custom shelving, equipment, and electronics (i.e. utility service vehicles)

- An electric power train is considerably simpler than an ICE system (e.g. over 1000 components in an ICE system is replaced by less than 100 components in an electric system reducing complexity by over 90%), simplifying and reducing maintenance e.g. no oil changes or spark-plug replacements needed

- EV models of many commercial vehicles currently in use are not yet available and the waitlist for new EVs that are is long, so it could take years to obtain enough vehicles

- Regulatory requirements demand changes, with many jurisdictions such as Europe and many US states are announcing sales/registration bans of new ICE vehicles and/or Zero Emissions Zones (ZEZs), taking effect in coming years

- It’s a great way to meet or accelerate ESG goals, as many companies are establishing decarbonization as part of their ESG, such as Amazon, which recently made its own voluntary commitment to decarbonize by 2040

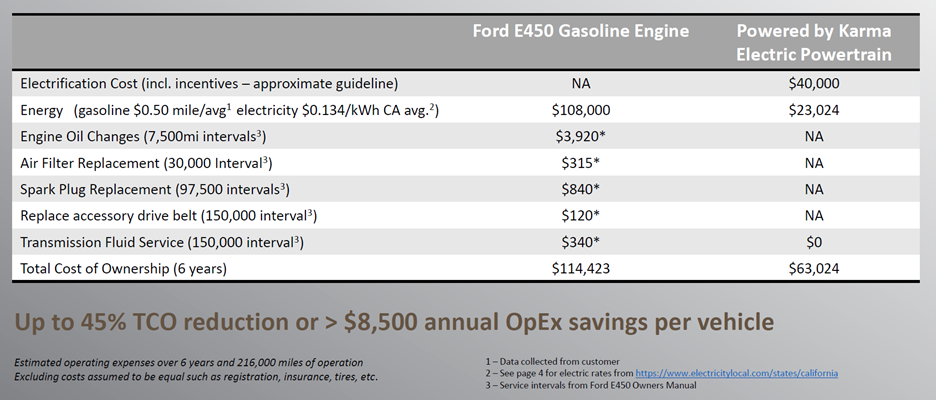

- Provides positive ROI –the initial investment is offset over time with lower operating costs and a lower total cost of ownership (TCO), especially in times of high gas prices and volatility

The electrification of a fleet gives companies the benefits of converting to electric without the long waits and costly expense of a complete replacement.

Process of Converting ICE to EV

It’s easy to see the benefits of converting a fleet rather than replacing it. But what is the process like? Does the time and money investment make it a realistic option?

The process is more cost-effective than replacing a fleet and is simple. Here is the process you’ll experience working with us at A3 Global and our partners.

- Bring in a few vehicles at a time to be converted (can process more vehicles depending on fleet size and customer needs)

- Once converted, we will return the vehicles to you, like a new EV

- Then the process is repeated with the next set of vehicles

For fleet owners, the process is simple and required little downtime; the process of converting a vehicle takes about a week.

The biggest hindrance to large-scale electrification across the world is the current battery supply chain. There are not enough lithium-ion batteries to fulfill demand. Fortunately, we have a strategic partner who provides us with priority access to high-quality battery packs for EV battery sales and conversions.

If your organization is considering converting your vehicles, then contact us. A3 Global brings innovation and expertise to the electrification aftermarket to offer turnkey solutions that align with customer needs and capabilities.

To subscribe to our monthly newsletter, click here.